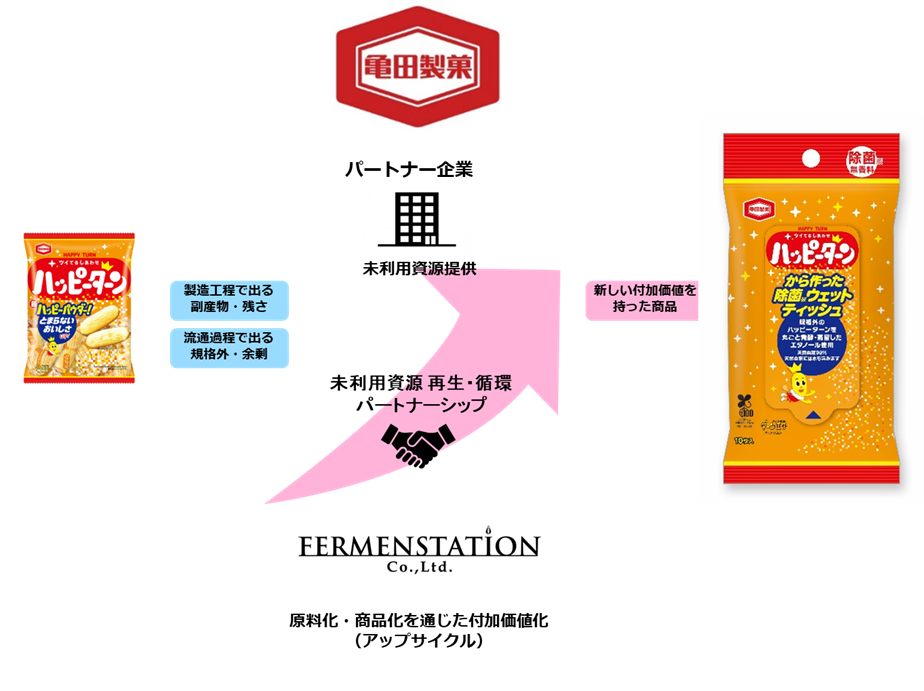

Fermenstation Co., Ltd. and Kameda Seika Co., Ltd. have collaborated to develop a groundbreaking product that upcycles unused resources. By utilizing off-spec products from the production process of Kameda’s iconic “Happy Turn” rice crackers, the companies have created disinfectant wet wipes infused with fermented ethanol. This innovative product will be used in promotional activities at select supermarkets starting in early December 2024.

Adding Value to Unused Resources

In an era where reducing food waste and minimizing environmental impact are critical, utilizing unused resources is becoming increasingly important. Fermenstation Co., Ltd. and Kameda Seika Co., Ltd. have implemented advanced upcycling technology as part of their commitment to a sustainable society. By transforming off-spec products from the “Happy Turn” production process into fermented ethanol, they have succeeded in incorporating it into disinfectant wet wipes.

Previously, off-spec rice cracker dough—resulting from under-baking or scorching—was recycled into animal feed. With this new technology, these by-products have been elevated into a high-value product. Notably, the wipes are 99% derived from natural materials, with biodegradable cellulose fabric used for the non-woven sheets, reflecting an eco-conscious approach.

This project is part of the “Re Kameda” initiative, launched by Kameda in May 2024 to create new value from by-products of rice cracker manufacturing. The development marks a significant advancement in the evolution of upcycling technologies, unlocking new potential for unused resources.

Moving forward, both companies aim to further expand their collaboration and accelerate the use of unused resources.