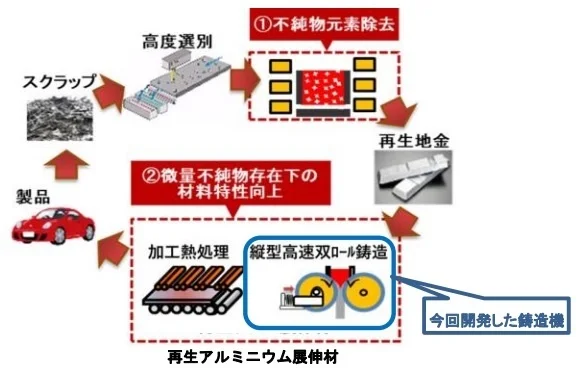

NEDO (New Energy and Industrial Technology Development Organization), in collaboration with UACJ Corporation and the Tokyo Institute of Technology, has developed the world’s first “Vertical High-Speed Twin-Roll Caster.” This new technology is expected to make it possible to manufacture rolled products using recycled aluminum, which has traditionally been difficult. It is scheduled to begin operations at UACJ’s R&D Center in Aichi Prefecture from October 2024.

Mass Production of High-Quality Recycled Materials Expected to Reduce CO2 Emissions

In today’s world, where a circular economy is highly demanded, aluminum is gaining attention, particularly in the transportation sector, as a lightweight material that contributes to reducing CO2 emissions. However, the production of new aluminum ingots emits significant amounts of CO2, making the use of recycled ingots increasingly important. Since 2021, NEDO has been working on the “Advanced Resource Recycling System for Aluminum Materials” project and, as part of this initiative, has been developing recycling technologies in collaboration with UACJ and Tokyo Institute of Technology.

Traditional technologies faced challenges in manufacturing rolled products from recycled aluminum due to impurities such as iron and silicon, which degraded the material’s properties. The newly developed “Vertical High-Speed Twin-Roll Caster” allows for the rapid casting of thin aluminum sheets directly from molten aluminum. By dramatically increasing the cooling rate—several tens of times faster than conventional methods—the technology enables a rapid solidification process. This significantly improves the quality of recycled materials by refining the impurities.

With this technology, mass production of aluminum rolled products using recycled materials is expected by 2030, ensuring a stable supply of high-quality recycled materials. Additionally, the technology could help reduce CO2 emissions by 18 million tons annually across the industry, making aluminum recycling more widespread and marking a major step towards achieving a circular economy.

Moving forward, the use of this casting machine is expected to further evolve mass production technology for recycled aluminum. Furthermore, as a new technology aimed at realizing a circular economy, it holds potential for application in other material fields. By 2050, the goal is to further reduce CO2 emissions across the industry and build a sustainable resource-circulating society.

visit homepage here.